Brake Inspection and Repair

- Identify Signs of Brake Issues: Some common signs indicating brake problems include:

- Squealing, grinding, or scraping noises when applying the brakes

- Soft or spongy brake pedal

- Vibrations or pulsations felt through the brake pedal or steering wheel when braking

- Longer stopping distances or decreased braking effectiveness

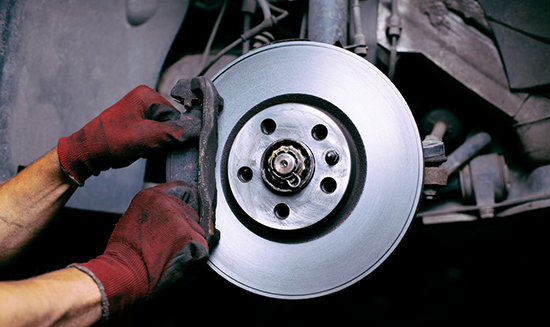

- Visual Inspection of Brake Components: Remove the wheels and visually inspect brake components, including brake pads, rotors, calipers, and brake lines, for signs of wear, damage, or corrosion. Look for uneven wear, grooves, cracks, or leaks that may indicate the need for brake repair.

- Measure Brake Pad Thickness: Use a brake pad gauge or caliper to measure the thickness of the brake pads. Replace brake pads if they are worn down to the minimum thickness specified by the manufacturer, typically around 1/8 to 1/4 inch (3 to 6 mm).

- Inspect Brake Rotors: Check the brake rotors for signs of wear, scoring, or warping. Measure rotor thickness using a micrometer to ensure it meets the manufacturer’s specifications. Replace rotors if they are too thin or if they have significant damage or warping.

- Check Brake Calipers: Inspect brake calipers for leaks, corrosion, or sticking pistons. Ensure that the calipers slide freely on their mounts and that the brake pads are making even contact with the rotors. Replace or rebuild calipers as needed to ensure proper braking performance.

- Inspect Brake Lines and Hoses: Check brake lines and hoses for signs of leaks, corrosion, or damage. Ensure that brake lines are not cracked, kinked, or rusted, and that hose connections are tight and secure. Replace damaged or deteriorated brake lines and hoses to prevent brake fluid leaks.

- Check Brake Fluid Level and Quality: Inspect the brake fluid level in the master cylinder reservoir and check its condition. Brake fluid should be clean and clear, with no signs of contamination or discoloration. Top off the brake fluid if necessary and flush the brake system periodically according to the manufacturer’s recommendations.

- Clean and Lubricate Brake Components: Clean brake components, including caliper slides, pad clips, and hardware, and lubricate them with brake grease or anti-seize compound as needed to ensure smooth operation and prevent binding or sticking.

- Replace Brake Hardware: Replace worn or damaged brake hardware, such as pad clips, shims, and anti-rattle springs, to ensure proper brake pad alignment and noise reduction.

- Perform Brake Bleeding (if necessary): If air has entered the brake system or if brake fluid has been replaced, bleed the brakes to remove air bubbles and ensure proper brake pedal feel and responsiveness.

- Reassemble and Test Brakes: Reassemble the brake components, reinstall the wheels, and torque the lug nuts to the manufacturer’s specifications. Test the brakes by performing a road test to ensure proper braking performance, pedal feel, and absence of noise or vibration.

- Document Service and Maintenance: Keep records of brake inspection, repairs, and maintenance performed, including brake pad and rotor replacement, fluid flushes, and any other brake-related services. This documentation helps track maintenance history and ensures timely servicing in the future.